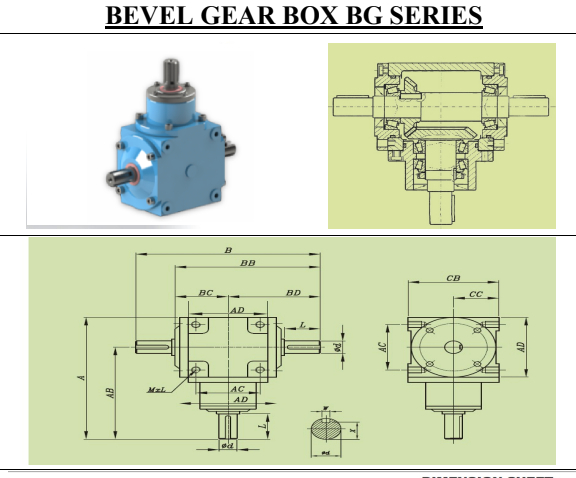

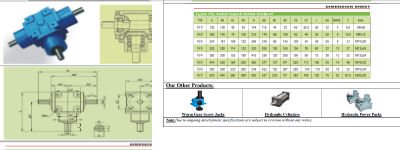

Bevel / Miter Gear Boxes

Bevel / Miter Gear Boxes

In Bevel Gear Screw Jacks the input shaft is perpendicular to the axis of actuator movement and the drive is transferred through a Bevel Gear Arrangement to the Lift Screw which can be either a Machined Screw or Ball Screw.

These jacks can be made only in rotating screw type. In such a jack arrangement the nut is attached to the moving part of the machine or arrangement.

The advantages of the Bevel Gear Screw Jacks are:

- High Speed : Such types of jacks can have higher lifting speeds than the worm gear screw jacks.

- Compact arrangement. : The box sizes are compact in comparison to the Worm Gear Screw

Jacks.

The limitations of the Bevel Gear Screw Jacks are:

- Low irreversibility: Mean the load may automatically start to move down when the motor is

switched off. In such a scenario one must use a brake motor in place of a regular motor. - Fixed mounting: Mounting arrangement is mostly fixed type.

- Design Arrangement : These are only available in rotating screw type.

Manufacturing Range:

Capacity: 1 ton to 50 Ton

Lifting Speeds : 4mm/Input Revolutions to 20mm/ Input Revolution

Construction Features:

- Body : Made of S.G. Iron ensures greater strength.

- Bevel Gear : Forged High Strength Alloy Steel Hardened and Tempered.

- Travel Nut: High Strength Cast Bronze ensuring long life and superior performance.

- Lift Screw : Precision rolled or machine cut Screw made from hogh strength Alloy steels.

- Ball Screw and Nut: High Quality High Precision Ball Screw and Nuts are used for

optimum strength and speed delivery.

©2022 Simran Flowtech Industries. All Rights Reserved. | Designed By  -Website Designing Company In Delhi

-Website Designing Company In Delhi